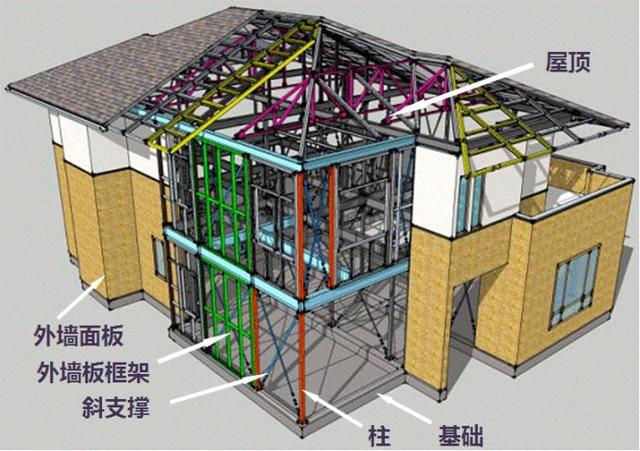

Steel-structure villas are known for their superior earthquake resistance. Compared to traditional brick houses, the materials used are much better in terms of strength and durability. Even during severe earthquakes, the structure will not completely collapse, minimizing casualties. Additionally, in many countries, steel is now commonly used in construction. If the house does not require rebuilding, the steel materials can be recycled and reused, making it highly environmentally friendly.

(1) Lightweight Floor System

The floor system consists of cold-formed, thin-walled C-shaped steel beams with structural panels laid on top. The typical span of these beams ranges from 3.6 to 6.0 meters, with a height of 200 to 300 mm and a spacing of 600 mm. Pre-drilled holes are made in the web of the floor beams, facilitating easy routing and installation of pipes and wiring.

The structural panels used in light steel villas are often oriented strand boards (OSB). Additionally, a 40 mm layer of fine aggregate concrete can be poured over the OSB for added strength. Depending on design requirements, the lightweight floor system can support a maximum load of 500 kg per square meter.

(2) Wall Structure

The load-bearing walls are composed of steel studs, top and bottom guide rails, bracing, and structural wall panels. The studs are made of C-shaped light steel, with wall thicknesses varying from 0.75 to 2 mm depending on the load. The typical spacing between studs is 400 to 600 mm. The bottom guide rail faces upward to hold the lower end of the studs, while the top guide rail faces downward to support the upper ends. For increased stability, one or two horizontal steel tie rods or braces are installed along the height of the wall. This configuration efficiently supports and transfers vertical loads while being easy to assemble.

To resist horizontal wind loads and seismic forces, the villa employs various lateral force-resisting systems, such as shear walls, cross-bracing, or K-bracing. Structural wall panels used as shear walls can include OSB, gypsum boards, cement fiberboards, or thin steel sheets. The upper and lower floors are securely connected with connectors to efficiently transfer shear forces and uplift forces.

(3) Roof Structure

The roof system adopts a light steel truss as the main load-bearing structure. The spacing between trusses can be arranged from 300 to 1200 mm depending on the roof load. Light purlins are installed on top of the trusses, with the purlin span reaching a maximum of 1800 mm.

The roofing material can be customized based on client preferences, with options including traditional cement tiles, ceramic tiles, stylish asphalt shingles, or colorful metal roof panels.

Since the entire roof system is a spatial truss structure, insulation and thermal layers can be integrated into both the sloping roof and suspended ceiling. The space between these layers allows for ventilation, enhancing airflow throughout the house. This design makes the villa more breathable, creating a comfortable living environment similar to a "breathing house."