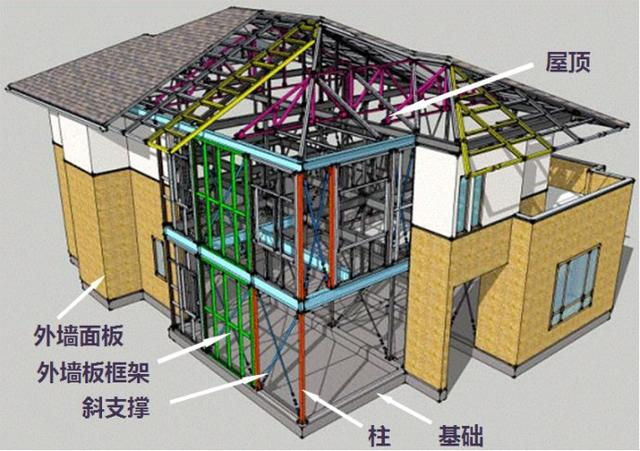

Steel structure villas refer to residential buildings that use steel or light steel as load-bearing beams and columns, with prefabricated insulation materials or gypsum boards as wall surfaces.

Development of Steel Structure Housing in China

During the 1960s and 1970s, large-panel buildings encountered numerous issues in functionality and structural safety. At the same time, the underdeveloped urban transport networks and the availability of low-cost migrant labor replacing industrial workers limited the economic and assembly advantages of industrialized housing. As a result, the use of steel structure housing diminished by the late 1980s. Over the following 20 years, concrete structures became the dominant choice due to their lower technical barriers and the higher wages of skilled workers compared to migrant labor.

In recent years, some regions in China began adopting steel structure housing from Europe and North America. However, China has primarily focused on foundation construction and assembly, without fully mastering the key structural technologies. While many areas are exploring the application of steel structure housing for villas, low-rise, and multi-story projects, these remain at the research and pilot stages. In 1999, the State Council issued Document No. 72, explicitly advocating for the development of steel structure housing and expanding its market share to accelerate housing industrialization. This initiative is expected to have a significant impact on the development of the construction, metallurgy, and related industries in China.

Development of Steel Structure Housing Abroad

In developed countries, the industrialization of light steel housing is advancing rapidly, with a high level of automation. Construction sites have shifted from being the primary place of building activity to adopting industrialized production methods. Sweden is currently the largest producer of light steel housing globally, with prefabricated components accounting for 95% of the structure. Many European countries source their housing components from Sweden for assembly back home. Since the last century, China has continuously collaborated with light steel housing companies from North America, Japan, and Australia to import advanced technologies.

Advantages of Steel Structure Housing

1. Lightweight and High Strength

Steel structure villas weigh approximately half as much as reinforced concrete houses. They meet the needs for larger interior spaces and provide about 4% more usable area than concrete houses. Additionally, the lightweight nature of steel reduces foundation costs.

2. Safety and Reliability

Steel structures offer excellent seismic and wind resistance, along with superior structural performance.

3. High-Quality Production and Shorter Construction Time

Steel components are prefabricated in factories, ensuring quality and reducing on-site work, which shortens the construction period and aligns with industrialization goals.

4. Precision and Ease of Assembly

Factory-made steel components are accurate in size, easy to install, and compatible with other building parts.

5. Recyclability and Environmental Benefits

Steel can be recycled, and both construction and demolition generate minimal pollution, making it more energy-efficient and eco-friendly compared to masonry and concrete.

6. Dust-Free Construction

No wet processes are required on-site, eliminating issues like dust pollution.

7. Thin Wall Sections and Increased Usable Area

The slender structure of steel components results in thinner walls, providing more usable space within the building.

This combination of structural efficiency, sustainability, and flexibility highlights the growing potential of steel structure housing as a key trend in modern residential development.